Power and performance come at a cost, that being weight. So when it comes to selecting an outboard for your boat, the balance of power and weight becomes an important issue in making the right choice. Until now, powering your boat with a 147kW (200PS) class outboard meant V6 power. That has all changed with Suzuki’s DF200A.

With the DF200A, our goal was to build an outboard that provides all of the power and performance of a 147kW (200PS) class V6 outboard using a lighter, more compact four-cylinder configuration.

To deliver that level of performance our engineers used an inline four-cylinder engine with a 2.9-liter “Big-Block” displacement and a higher 10.2:1 compression ratio to generate impressive acceleration and low-end torque. A specially designed cowl and semi-direct air intake system were designed to provide cooler air to the tuned long-track intake manifold while a four valve per cylinder DOHC powerhead with Variable Valve Timing lets the engine breathe more efficiently increasing acceleration and top end speed.

Added to that are a fuel injection system and Suzuki’s Lean Burn Technology for improved fuel economy. The DF200A weighs 30kg less and is more compact than the V6 version. That and its excellent balance when mounted on the transom make it the perfect choice for powering lightweight boats. It’s also great for breathing new life into older boats still rigged with lighter two-stroke engines, giving them the latest in four-stroke technology and economy without sacrificing on weight or power.

Other features include a knock sensor, O2 sensor, and water detecting system to provide superior reliability.

Big Block—High Performance Engine

The design goal for the new DF200A was to provide boaters with the performance of a V6 DF200 outboard from a more compact, lighter weight four-cylinder engine. For this, Suzuki engineers started with the 2.9-liter straight four block used on DF150/175, updating the “Big Block” design with a DOHC four-valve per cylinder powerhead and a 10.2:1 compression ratio. In addition, the engine incorporates Variable Valve Timing, Multi-stage Induction, and a 32-bit on board computer. The end result is an engine that weighs 30kg less than the V6 version making it an excellent choice for powering bass boats and other lightweight vessels. It’s also an excellent choice for those wanting to upgrade older boats fitted with V6 two-strokes.

Higher Compression Ratio 10.2:1

Drawing upon our experience building race engines for motorsports, Suzuki engineers have designed the DF200A’s in-line four-cylinder engine with a higher compression ratio of 10.2:1. The higher compression ratio delivers a noticeable improvement in performance and power output from the engine’s 2,867cm3 displacement.

Largest Displacement in Its Class

Displacement has a direct effect on acceleration and torque.

For that reason, the DF200A is designed with a 2,867cm3 displacement making it the largest available in the 147kW (200PS) four-cylinder four-stroke class.

VVT (Variable Valve Timing)

Variable Valve Timing is utilized on many of Suzuki’s high end outboards to deliver high performance across the outboard’s full power band while retaining the benefits that four-stroke technology provides. The system starts with an innovative cam profile designed for delivering maximum output and performance at high rpm. Variable Valve Timing is used to vary intake timing with the camshaft to optimize timing for low to mid-range operation. This allows the engine to deliver maximum power output across its entire operating range producing greater low to mid-range torque for powerful acceleration. The entire process happens automatically leaving you to enjoy the power and performance.

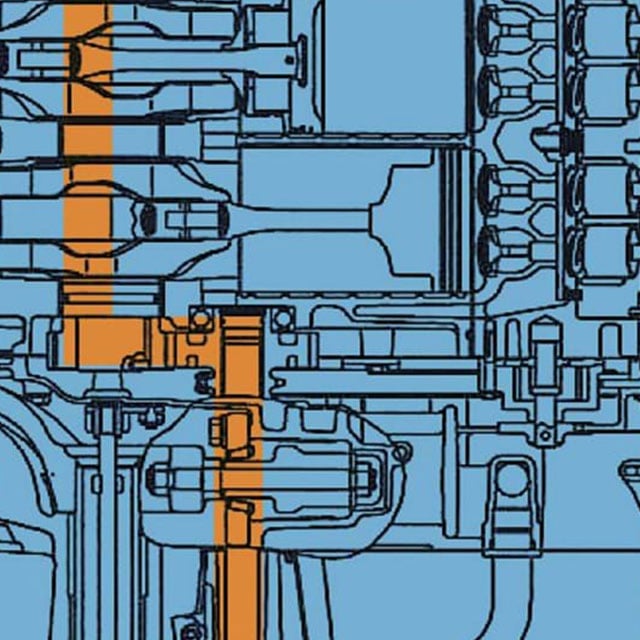

Multi-Stage Induction (MSI)

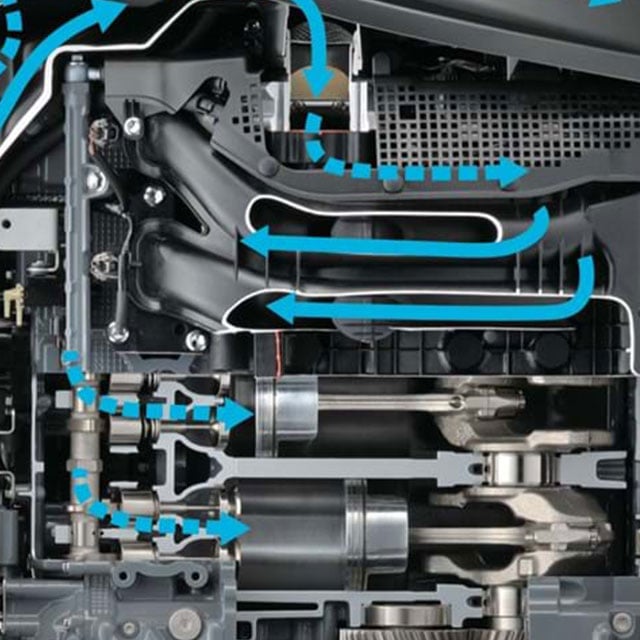

Getting the right amount of air into the cylinder has a great impact on performance. High-speed operation typically requires a greater volume of air, low-speed less. Suzuki’s Multi-Stage Induction system meets these needs by utilizing two intake manifold pipes per cylinder to ensure the engine gets the right amount of air. At low rpm, air enters the combustion chamber through a longer, curved manifold pipe designed to improve combustion and boost low end torque. As rpm increases, the valves open on the direct intake pipes. Shorter and lacking resistance, these pipes allow a greater volume of air into the chamber, increasing the engine’s ability to breathe efficiently at high rpm resulting in higher power output during high-speed operation.

Counter Balancer System

One of the inherent characteristics common to in-line four cylinder engines when operating at high rpm is a secondary vibration that is directionally in line with the piston’s movements. To neutralize this vibration, Suzuki engineers utilize a secondary balancer system that counters the piston’s movement with a horizontal motion. To achieve this, the balancer is divided into left and right sections each rotating in an opposite direction at twice the speed of the crankshaft, effectively countering the secondary vibrations and producing smoother engine operation.

DF200APX

DF200APX

DF200APL

DF200APL

Electronic Fuel Injection

Drive By Wire

Selective Rotation

Electronic Fuel Injection

Drive By Wire

Selective Rotation

Function for selecting regular or counter rotation on one outboard with an optional connector.

Operation from the remote control is delivered to outboard via an electric signal and not by the traditional mechanical control cables.

The Lean Burn Control System supplies the right fuel and air mixture depending on the navigation conditions.

The timing chain runs in an oil-bath so it never needs lubricating, and is equipped with an automatic hydraulic tensioner so it remains properly adjusted at all times.

It helps protect the engine from water in the fuel using a water detecting fuel filter to alert the operator with both visual and audio warnings when water is present in the fuel.

Intake noise is Resonator suppressed with a resonator, which makes the noise from the outboard quieter.

The offset drive allows us to make our outboard engines smaller by moving the outboards centre of gravity forward, improving weight distribution, power output, balance and reduces vibration.

Multi-stage induction enhances the engines performance by allowing the right amount of air into the cylinder resulting in higher power output during high speed operation.

| Bore x stroke | 97 × 97mm |

| Starting system | Electric |

| Maximum output | 147.0kw |

| Full throttle operating range | 5,500-6,100rpm |

| Gear shift | F-N-R |

| Displacement | 2.867cm3 |

| No of cylinders | In-line 4 |

| Oil pan capacity | 8.0 litres |

| Shaft length | L: 508 | X: 635mm |

| Ignition system | Fully-transistorized |

| Trim method | Power trim & tilt |

| Exhaust | Through Prop Hub Exhaust |

| Weight | L: 228 | X: 233kg |

| Steering | Remote |

| Gear ratio | 2.50:1 |

| Hs initial published at | 1740649000375 |

| Engine type | DOHC 16-Valve |

| Engine mounting | Shear mount |

| Fuel delivery system | Multi-point sequential electronic fuel injection |

| Propeller selection pitch | 15”-27.5” |

| Alternator | 12V 44A |