We are proud to introduce our NEW DF325A – an outboard that perfectly balances awesome power and thrust, with outstanding fuel-efficiency and trusted reliability all within a lightweight and stylish design.

Built with the every-day use of larger boats in mind, this market-leading new outboard has been engineered to run on 91 RON fuel and, as a world-first, is the first four stroke outboard over 300 horsepower to do so.

The high-tech and innovative DF325A has been designed to be robust, easy to use and versatile, making it the ideal outboard for large boats whatever the task.

Whether you are using your boat for work or play, wherever you are in the world, this new outboard is the ultimate choice.

Features

RON FUEL

Our engineers set out to build a compact, lightweight outboard that combines the high power required, alongside the operating efficiencies that cannot be achieved by using technologies such as turbocharging or supercharging. Additionally, they set the goal of making the DF325A run on low octane, 91 RON fuel, which combined with legendary Suzuki reliability makes the outboard ideally suited for a wide variety of large boats around the world.

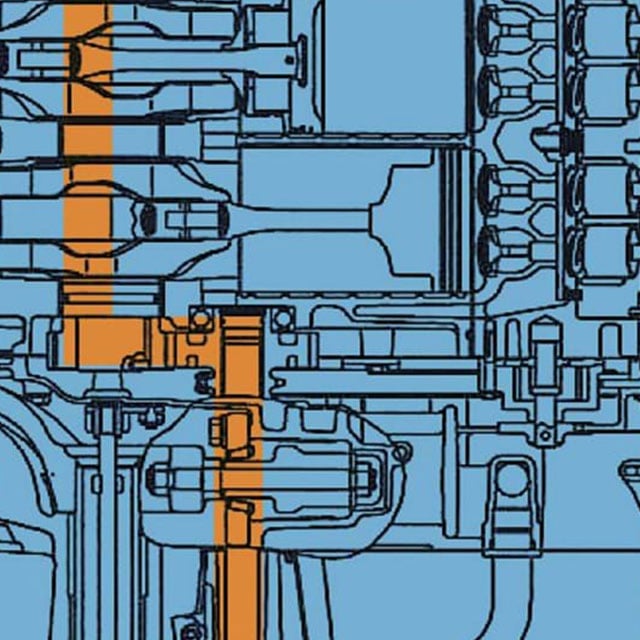

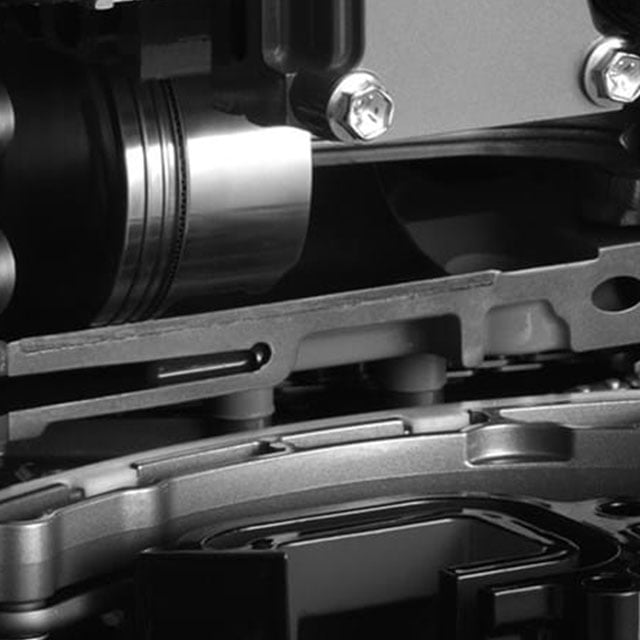

COMPRESSION RATIO

Our solution to developing 74 horsepower per litre in a V6 325 horsepower engine was to increase the compression ratio to 10.5:1, the highest compression ratio ever for a production outboard engine. In order to make this work without knocking (a typical problem at this ratio), we developed systems to mix cooler air with well-atomized fuel to provide optimal conditions for complete, and controlled combustion.

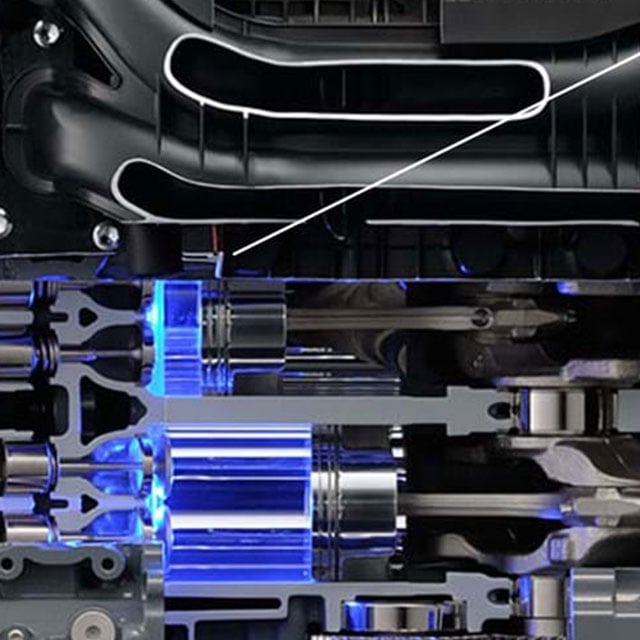

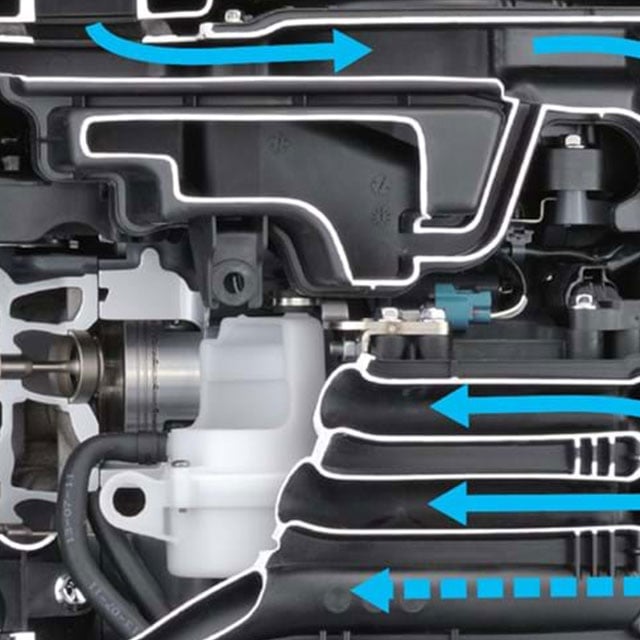

DIRECT INTAKE SYSTEM AND DUAL LOUVER SYSTEM

At high speed, water particles could be directed, trapped, and drained away. Our experienced engineers worked on applying this theory to practice by increasing the intake flow to convert water vapour to particles and designing blades to capture and deflect those particles away from the intake flow. The Dual Louver System incorporates a double shield of blades, each one designed in a dog-leg shape. The outer row of blades removes the spray from the boat and the inner louvers capture and drain the remaining mist. As a result, intake air temperature is free of moist and no higher than 10° above ambient

DUAL INJECTORS

Injecting fuel does two things, it atomizes the fuel and, incidentally, it cools the cylinder to minimize knock. To achieve the power we wanted, we needed to inject 100% of the fuel into the cylinder all at once, at a precise time, and at a precise angle to both cool the cylinder and to allow combustion to take place in the centre of the combustion chamber. The new Dual Injector System using two smaller injectors provided the required precision as well as improved atomization, increasing output by 3% without causing knocking.

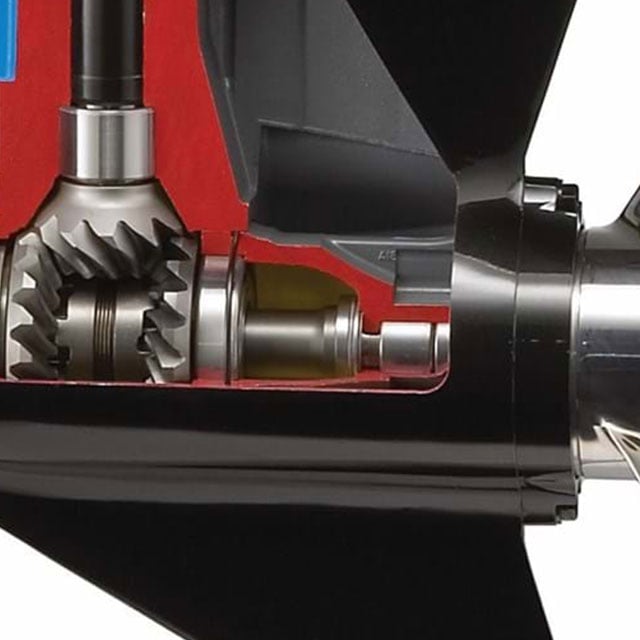

CONTRA-ROTATING PROPELLER

The contra-rotating propeller provides more “grip” underwater, and because contra-rotating props distribute the engine torque evenly over two propellers, the torque per propeller decreases and gear diameter can be reduced. This makes a reduction in gear diameter possible, which could then lead to the design of a smaller, more hydrodynamic gear case.

PROPELLER BLADE DESIGN

A new three-blade front/three-blade back propeller set-up was developed that provided improved performance on the water. This new set up provided not only the highest recorded speeds for the DF325A, but also delivered incredible acceleration, even under heavy load and at high rotation speeds.

DUAL WATER INTAKES

On the DF325A, the best results were achieved when the main intake was positioned at the front of the gear case, with the secondary intake located just above the skeg. This was our ultimate solution to arranging the main and sub intakes as far apart from each other as possible, and designing them to ensure a reliable amount of cooling water, especially at high speeds.

DESIGNING STRONGER REVERSE THRUST

The gear material was changed and heat treatment was added to endure the added thrust and inertial mass from the reverse thrust, which was stronger on a contra-rotating propeller. In addition, the reverse gear was moved above the cavitation plate and the position of the lower engine mounts was modified from parallel to V-shape to fit the reverse gear above the cavitation plate.

BETTER STEERING IN ALL DIRECTIONS

Normally, when using multiple outboards a combination of standard and counter-rotating engines is mounted. The Suzuki Selective Rotation, available on our AP series outboards, eliminates the need for different models, as any model can be easily programmed to run in either direction. The DF325A’s contra-rotating propeller technology takes this process one step further by eliminating steering torque and maximizing true and straight propulsion forces.